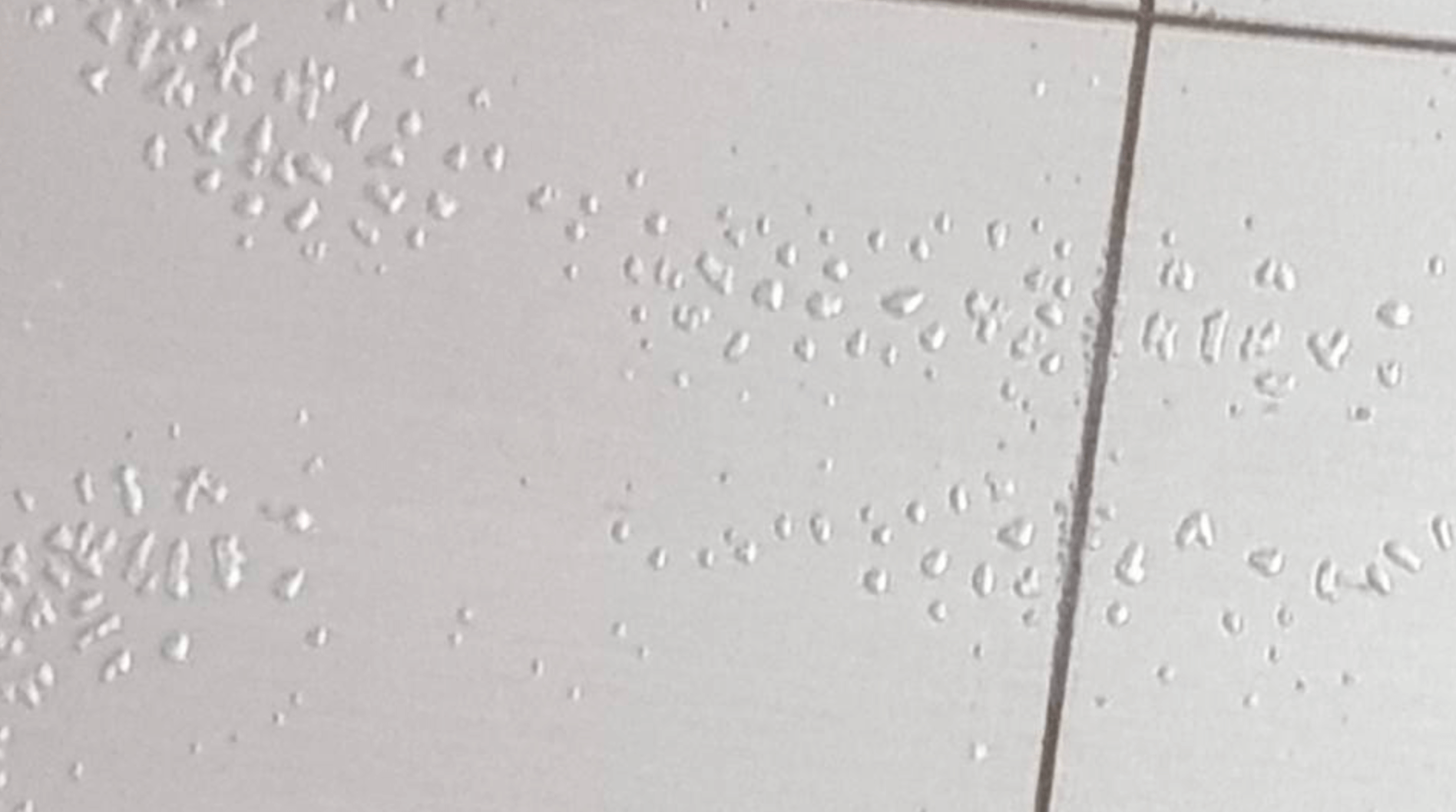

Over time, you might see some small bubbles underneath the PEI. This is nothing serious. These bubbles usually do not affect print quality and will disappear after a few days or weeks. Here are 2 tips that will make these bubbles disappear faster:

Bubbles under PEI sheet

After several hours of printing, various kinds of debris may start to accumulate around the printer parts or under the heatbed - pieces of filament, dust, scraps, broken supports, etc. Always make sure that the parts of the printer are clean. You can use a brush, a small broom, or a vacuum to remove debris.

It is fundamental for the hotend to be clean. Debris on the nozzle or heaterblock can cause printer failures, for example with the residue falling onto the printed model while the print is in progress.

To clean the nozzle and heaterblock, heat the nozzle for three to five minutes at 250 °C, as the remains of the filament must be warmed up slightly so that they can be removed more easily.

Use a small brass brush to clear away any old plastic stuck on the nozzle and heaterblock.

Avoid contact of the brush with the hotend cables, as this could cause a short circuit.

Caution: the printer is still at a hot temperature! Wait until the hot parts are cooled down to ambient temperature. It takes approximately 10 minutes. Do not touch it! Always check the values on the display.

Disclaimer: This website includes links to non-PPLD websites and services. PPLD cannot control the content or functionality of non-PPLD websites or services nor endorse the accessibility or accuracy of those sites. Users should use critical judgment in relying on information found in these resources and determine what information is appropriate to their needs.

This website also links to documents that may not be fully accessible, documents can be made accessible by request. Please visit our Accessibility page for more information.